Understanding Oil Sands Mining: A Detailed Insight

Have you ever wondered what goes on behind the scenes of oil sands mining? This process, often referred to as “tar sands” extraction, is a significant part of the global oil industry. In this article, we delve into the intricacies of oil sands mining, exploring its environmental impact, economic implications, and the technological advancements that have made it possible.

What are Oil Sands?

Oil sands, also known as tar sands, are a mixture of sand, clay, water, and a thick, sticky form of crude oil called bitumen. These deposits are found in large quantities in Canada, specifically in the provinces of Alberta and Saskatchewan. The bitumen in oil sands is a heavy, dense form of crude oil that requires significant processing to be refined into usable fuel.

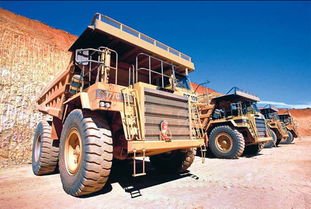

How is Oil Sands Mining Conducted?

There are two primary methods of oil sands mining: open-pit mining and in-situ mining.

Open-pit Mining: This method involves removing the topsoil and overburden to expose the oil sands. The sand is then separated from the clay and water, and the bitumen is extracted using various techniques, such as steam-assisted gravity drainage (SAGD) or cyclic steam stimulation (CSS). The extracted bitumen is then transported to a processing facility for further refinement.

In-situ Mining: In this method, the bitumen is extracted directly from the ground without removing the overburden. This is achieved by injecting steam into the oil sands to heat the bitumen, making it easier to extract. The heated bitumen is then pumped to the surface for processing.

The Environmental Impact of Oil Sands Mining

While oil sands mining has provided significant economic benefits, it has also raised concerns about its environmental impact.

Water Usage: Oil sands mining requires vast amounts of water for extraction and processing. This has led to concerns about water scarcity and the potential for contamination of local water sources.

Greenhouse Gas Emissions: The extraction and processing of oil sands produce significant amounts of greenhouse gases, contributing to climate change. In fact, oil sands are considered to be one of the most carbon-intensive sources of oil.

Land Disturbance: Both open-pit and in-situ mining methods result in significant land disturbance, including deforestation and the destruction of natural habitats.

Economic Implications of Oil Sands Mining

Despite the environmental concerns, oil sands mining has had a significant economic impact on Canada.

Job Creation: The oil sands industry has created thousands of jobs, both directly and indirectly, in Canada. This has helped to stimulate the local economy and reduce unemployment rates.

Revenue Generation: The oil sands industry generates significant revenue for the Canadian government, which is used to fund public services and infrastructure projects.

Technological Advancements in Oil Sands Mining

Over the years, technological advancements have made oil sands mining more efficient and environmentally friendly.

Improved Extraction Techniques: New extraction techniques, such as SAGD and CSS, have reduced the amount of water and energy required for extraction.

Carbon Capture and Storage (CCS): Researchers are working on CCS technologies to capture and store the greenhouse gases produced during oil sands mining, reducing their impact on the environment.

Conclusion

Oil sands mining is a complex and controversial process with significant economic and environmental implications. While it has provided economic benefits, it has also raised concerns about its impact on the environment. As technology continues to evolve, it is crucial to find a balance between economic growth and environmental protection.

| Method | Water Usage (liters) | Energy Consumption (MJ) |

|---|---|---|

| Open-pit Mining | 3-5 | 2,000-3,000 |

| In-situ Mining | 1-2 | 1,500-2,500 |