Fine Silica Sand: A Comprehensive Overview

Fine silica sand, often referred to as quartz sand, is a highly sought-after material in various industries. Its unique properties make it an essential component in numerous applications. In this article, we will delve into the characteristics, production, uses, and benefits of fine silica sand.

Characteristics of Fine Silica Sand

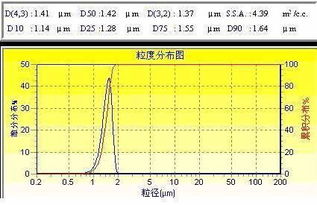

Fine silica sand is primarily composed of silicon dioxide (SiO2), which is the main constituent of quartz. This mineral is known for its hardness, durability, and resistance to chemicals. The particle size of fine silica sand ranges from 0.0625 to 0.25 mm, making it suitable for various applications.

Fine silica sand is primarily composed of silicon dioxide (SiO2), which is the main constituent of quartz. This mineral is known for its hardness, durability, and resistance to chemicals. The particle size of fine silica sand ranges from 0.0625 to 0.25 mm, making it suitable for various applications.

One of the key characteristics of fine silica sand is its high purity. It contains less than 1% of impurities, which ensures its quality and effectiveness in different industries. The sand is also known for its excellent thermal conductivity, making it a preferred choice for heat exchangers and other thermal applications.

Production of Fine Silica Sand

The production of fine silica sand involves several steps, starting from the extraction of raw materials to the final processing. Here’s a brief overview of the process:

The production of fine silica sand involves several steps, starting from the extraction of raw materials to the final processing. Here’s a brief overview of the process:

-

Extraction: Fine silica sand is extracted from natural sources, such as riverbeds, lakes, and quarries. The raw material is then transported to the processing plant.

-

Washing: The raw material is washed to remove any impurities, such as clay, silt, and organic matter. This step ensures the purity of the sand.

-

Classifying: The washed sand is then classified based on particle size using various techniques, such as screens and cyclones.

-

Drying: The classified sand is dried to remove any moisture content, which can affect its quality and performance.

-

Grinding: In some cases, the sand is ground further to achieve a finer particle size, as required by specific applications.

Applications of Fine Silica Sand

Fine silica sand finds extensive use in various industries due to its unique properties. Here are some of the primary applications:

Fine silica sand finds extensive use in various industries due to its unique properties. Here are some of the primary applications:

| Industry | Application |

|---|---|

| Construction | As an ingredient in concrete, mortar, and asphalt. |

| Foundry | As a molding material for metal casting. |

| Chemical | As a raw material for the production of glass, ceramics, and silicones. |

| Water Treatment | As a filter medium to remove impurities from water. |

| Paints and Coatings | As a pigment and extender to improve the properties of paints and coatings. |

Benefits of Fine Silica Sand

Fine silica sand offers several benefits, making it a preferred choice in various industries:

-

High Purity: The high purity of fine silica sand ensures its effectiveness in different applications.

-

Excellent Thermal Conductivity: Its high thermal conductivity makes it suitable for heat exchangers and other thermal applications.

-

Chemical Resistance: The sand’s resistance to chemicals makes it ideal for use in chemical industries.

-

Cost-Effective: Fine silica sand is a cost-effective material, making it accessible to various industries.

In conclusion, fine silica sand is a versatile and essential material with a wide range of applications. Its unique properties, coupled with its cost-effectiveness, make it a preferred choice in various industries. As the demand for fine silica sand continues to grow, it is crucial for manufacturers and consumers to understand its characteristics, production, and uses to make informed decisions.