Sand Roller Machine: A Comprehensive Guide

Are you looking to enhance the quality of your sanding projects? If so, a sand roller machine might just be the tool you need. In this detailed guide, we will delve into the various aspects of a sand roller machine, including its features, benefits, and how to use it effectively.

Understanding the Basics

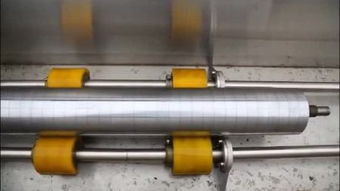

A sand roller machine is a versatile tool designed for sanding large surfaces efficiently. It is particularly useful for smoothing out rough surfaces, removing paint, and preparing surfaces for painting or coating. Unlike traditional sandpaper, a sand roller machine allows for a more even and consistent finish.

Here’s a brief overview of the key components of a sand roller machine:

- Roller Head: This is the part that comes into contact with the surface being sanded. It is typically made of durable materials like aluminum or steel.

- Handle: The handle provides a comfortable grip and allows for easy maneuverability.

- Drive Mechanism: This component powers the roller head, enabling it to sand the surface effectively.

- Adjustable Settings: Many sand roller machines come with adjustable settings to accommodate different sandpaper grit sizes and surface types.

Benefits of Using a Sand Roller Machine

There are several advantages to using a sand roller machine over traditional sanding methods:

- Increased Efficiency: A sand roller machine can cover large surfaces much faster than manual sanding, saving you time and effort.

- Consistent Finish: The even pressure applied by the roller head ensures a consistent finish, reducing the risk of uneven sanding.

- Reduced Strain: Sanding large surfaces manually can be physically demanding. A sand roller machine helps alleviate this strain, making the job more comfortable.

- Improved Safety: The roller head reduces the risk of sandpaper tearing or jamming, which can be a safety hazard.

Choosing the Right Sand Roller Machine

When selecting a sand roller machine, consider the following factors:

- Size: Choose a machine that is suitable for the size of the surface you need to sand. Larger machines are better for larger surfaces, while smaller machines are more suitable for smaller projects.

- Power: Look for a machine with a powerful motor to ensure efficient sanding. A motor with at least 1 horsepower is recommended for most applications.

- Adjustable Settings: A machine with adjustable settings allows you to customize the sanding process to suit your specific needs.

- Ease of Use: Consider the machine’s design and features to ensure it is easy to use and maintain.

How to Use a Sand Roller Machine

Using a sand roller machine is a straightforward process. Here’s a step-by-step guide:

- Attach the Sandpaper: Place the desired grit size of sandpaper on the roller head. Ensure it is securely attached and free of wrinkles or creases.

- Adjust the Settings: If your machine has adjustable settings, set them according to the surface type and desired finish.

- Start Sanding: Begin sanding the surface in a straight line, applying even pressure. Avoid pressing too hard, as this can cause the sandpaper to tear or jam.

- Change Sandpaper: As the sandpaper becomes clogged with debris, it will lose its effectiveness. Replace it with a fresh piece as needed.

- Finish the Job: Once the surface is smooth and even, remove the sandpaper and inspect the work. If necessary, repeat the process with a finer grit size for a more polished finish.

Common Uses of Sand Roller Machines

Sand roller machines are widely used in various industries and applications, including:

- Construction: Preparing surfaces for painting, coating, or finishing work.

- Automotive: Sanding vehicle bodies, doors, and other components.

- Woodworking: Smoothing out wooden surfaces, furniture, and cabinets.