Lightning Sand to Glass: A Journey Through the Miraculous Transformation

Have you ever wondered how the shimmering sands of the desert can be transformed into the clear, transparent glass that we use in our everyday lives? The process is both fascinating and intricate, involving a series of steps that turn raw materials into a valuable commodity. Let’s embark on a journey to understand the transformation from lightning sand to glass.

Understanding the Raw Material

The journey begins with the raw material, which is a type of sand known as “lightning sand” or “soda ash.” This sand is composed primarily of sodium carbonate, which is a key ingredient in glass production. The sand is typically found in arid regions, where it is easily extracted and processed.

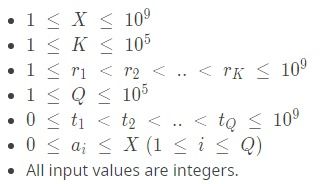

Table 1: Composition of Lightning Sand

| Component | Percentage |

|---|---|

| Sodium Carbonate (Na2CO3) | Na2CO3: 60-70% |

| Silica (SiO2) | SiO2: 15-25% |

| Other Minerals | Other: 5-10% |

The Extraction Process

Once the lightning sand is extracted, it undergoes a series of processes to purify and prepare it for glass production. The first step is to crush the sand into smaller particles, which are then mixed with water to form a slurry. This slurry is then heated to remove impurities and to convert the sodium carbonate into a more usable form.

The Melting Process

After the sand has been purified, it is mixed with other raw materials, such as silica sand and limestone, to create a batch of glass. This batch is then melted in a furnace at temperatures exceeding 1,600 degrees Celsius. The intense heat causes the batch to melt and form a liquid, which is the basis for glass production.

The Forming Process

Once the glass has been melted, it is ready to be formed into various shapes and sizes. The most common methods of forming glass include blowing, casting, and drawing. Blowing involves using a blowpipe to shape the glass into a bubble, which is then manipulated into the desired shape. Casting involves pouring the molten glass into molds, while drawing involves pulling the glass through a series of molds to create a sheet or tube.

The Finishing Process

After the glass has been formed, it undergoes a series of finishing processes to improve its quality and appearance. These processes include annealing, which involves slowly cooling the glass to relieve internal stresses, and tempering, which involves heating the glass to a high temperature and then rapidly cooling it to create a strong, durable surface.

The Applications of Glass

Once the glass has been produced, it is used in a wide range of applications, from windows and doors to bottles and jars. Glass is also used in the construction industry, where it is used to create glass facades, partitions, and floors. Additionally, glass is used in the electronics industry, where it is used to create screens and displays.

The Environmental Impact

While the process of transforming lightning sand into glass is fascinating, it is also important to consider the environmental impact. The production of glass requires significant amounts of energy and resources, and it also produces greenhouse gases. However, advancements in technology and sustainable practices are helping to reduce the environmental impact of glass production.

In conclusion, the journey from lightning sand to glass is a remarkable transformation that involves a series of steps and processes. From the extraction of raw materials to the final finishing touches, the process is both intricate and fascinating. As we continue to innovate and improve the production of glass, we can look forward to a future where this versatile material continues to serve a wide range of applications.