Furan Resin Sand Casting: A Comprehensive Guide

Furan resin sand casting is a popular metal casting process that has been widely used in various industries due to its numerous advantages. In this article, we will delve into the details of this casting method, exploring its history, materials, process, applications, and benefits.

History of Furan Resin Sand Casting

The concept of using resin sand for casting originated in the early 20th century. Furan resin, a type of thermosetting resin, was first introduced in the 1950s. Since then, it has gained popularity in the casting industry due to its excellent properties and environmental benefits.

Materials Used in Furan Resin Sand Casting

Furan resin sand casting primarily uses two types of materials: the sand and the resin binder. The sand is typically made from quartz, which is a hard, durable, and chemically inert material. The resin binder, which holds the sand grains together, is made from furan resin, a thermosetting polymer derived from furfural, a byproduct of the corn processing industry.

Table 1: Comparison of Materials Used in Furan Resin Sand Casting

| Material | Description | Source |

|---|---|---|

| Sand | Quartz-based sand, hard and durable | Quartz mines |

| Resin Binder | Furan-based thermosetting polymer | Furfural byproduct from corn processing |

Process of Furan Resin Sand Casting

The process of furan resin sand casting involves several steps, including mold preparation, core making, metal pouring, and cooling. Here’s a brief overview of each step:

-

Mold Preparation: The sand is mixed with the resin binder to form a mold. The mixture is then compacted and cured to create a solid mold.

-

Core Making: If the casting requires internal cavities, cores are made using the same process as the mold. These cores are then placed inside the mold.

-

Metal Pouring: The molten metal is poured into the mold, filling the cavities created by the sand and cores.

-

Cooling: The metal is allowed to cool and solidify inside the mold. Once solidified, the mold is broken, and the casting is removed.

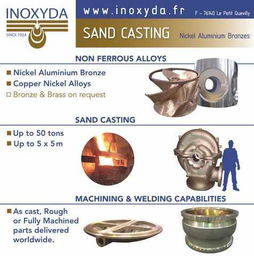

Applications of Furan Resin Sand Casting

Furan resin sand casting is used in various industries, including automotive, aerospace, and heavy machinery. Some common applications include:

-

Automotive: Engine blocks, cylinder heads, and exhaust manifolds.

-

Aerospace: Engine components, landing gear, and airframe structures.

-

Heavy Machinery: Gearboxes, pump bodies, and hydraulic systems.

Benefits of Furan Resin Sand Casting

Furan resin sand casting offers several advantages over traditional casting methods, such as:

-

High Strength: The cured sand mold provides excellent strength and rigidity, allowing for the production of complex shapes.

-

Good Dimensional Accuracy: The process ensures high precision in the dimensions of the casting, reducing the need for post-processing.

-

Environmental Benefits: Furan resin is a non-toxic, environmentally friendly material that is biodegradable.

-

Cost-Effective: The process is cost-effective, as it requires less energy and raw materials compared to traditional casting methods.

In conclusion, furan resin sand casting is a versatile and efficient casting method that offers numerous benefits. Its wide range of applications and environmental advantages make it a preferred choice for many industries. As technology continues to advance, we can expect to see further improvements and innovations in this casting process.