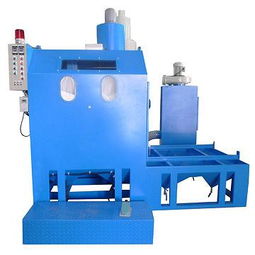

Sand Blasting Machine Industrial: A Comprehensive Guide

Are you looking to enhance the surface preparation process in your industrial setting? If so, a sand blasting machine could be the perfect solution. This article will delve into the details of sand blasting machines, their industrial applications, and how they can benefit your business.

Understanding Sand Blasting Machines

Sand blasting machines are used to clean, smooth, and prepare surfaces by propelling a stream of abrasive material, such as sand, at high velocity. These machines come in various types, each designed for specific applications. Let’s explore the different types of sand blasting machines available in the industrial sector.

| Type | Description |

|---|---|

| Wet Sand Blasting | Utilizes water to control dust and reduce the risk of fire. Suitable for delicate surfaces and environments where dust control is crucial. |

| Dry Sand Blasting | Does not use water and is more aggressive. Ideal for heavy-duty cleaning and surface preparation tasks. |

| Airless Sand Blasting | Operates at high pressure without the use of air. This method is faster and more efficient, making it suitable for large-scale projects. |

| Water Jet Sand Blasting | Combines water and abrasive materials to achieve a high-pressure cleaning effect. Suitable for removing coatings and contaminants from surfaces. |

Each type of sand blasting machine has its own advantages and is suitable for different applications. It’s essential to choose the right machine based on your specific needs.

Industrial Applications of Sand Blasting Machines

Sand blasting machines are widely used in various industries for surface preparation and finishing tasks. Here are some of the most common applications:

-

Automotive Industry: Sand blasting machines are used to clean and prepare car bodies, engines, and other components before painting or coating.

-

Construction Industry: These machines are used to clean concrete surfaces, remove old paint, and prepare surfaces for new coatings.

-

Marine Industry: Sand blasting machines are used to clean ship hulls, propellers, and other marine equipment to remove barnacles, rust, and corrosion.

-

Manufacturing Industry: These machines are used to clean and prepare metal parts, remove burrs, and achieve a smooth finish.

-

Art Restoration: Sand blasting machines are used to clean and restore historical artifacts, such as sculptures and monuments.

These applications highlight the versatility and effectiveness of sand blasting machines in the industrial sector.

Benefits of Using Sand Blasting Machines

Investing in a sand blasting machine can bring numerous benefits to your industrial operations. Here are some of the key advantages:

-

Improved Surface Quality: Sand blasting machines can achieve a high-quality finish, resulting in better adhesion of coatings and paints.

-

Increased Efficiency: These machines can handle large-scale projects quickly and efficiently, reducing labor costs and downtime.

-

Enhanced Safety: Sand blasting machines can remove hazardous materials, such as rust, paint, and contaminants, creating a safer working environment.

-

Cost-Effective: While the initial investment may be significant, sand blasting machines can provide long-term cost savings by reducing labor and material waste.

By incorporating sand blasting machines into your industrial operations, you can improve the quality of your products, increase efficiency, and create a safer work environment.

Choosing the Right Sand Blasting Machine

When selecting a sand blasting machine for your industrial needs, consider the following factors:

-

Size and Capacity: Ensure the machine can handle the size and volume of your projects.

-

Power Source: Choose a machine that operates on the power source available in your facility.

-

Material Compatibility: Select a machine that can handle the materials you need to clean and prepare.

-

Portability: If you require mobility, opt for a machine that