Sand Ball Bearing Table: A Comprehensive Guide

Are you looking to enhance the functionality and efficiency of your machinery? If so, you might want to consider investing in a sand ball bearing table. This versatile piece of equipment is widely used in various industries for its durability and reliability. In this article, we will delve into the details of sand ball bearing tables, covering their construction, applications, and benefits. Let’s get started.

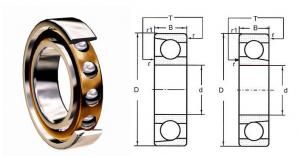

Understanding Sand Ball Bearings

Sand ball bearings are a type of rolling bearing that utilizes sand particles as the rolling elements. Unlike traditional ball bearings, which use steel balls, sand ball bearings offer several advantages, such as reduced friction, higher load capacity, and longer service life. The sand particles are typically made of silicon carbide or ceramic materials, providing excellent wear resistance and heat dissipation properties.

Construction of Sand Ball Bearing Tables

Sand ball bearing tables are designed to accommodate the installation and maintenance of sand ball bearings. They are typically made of high-quality steel, ensuring durability and stability. The table consists of several key components:

-

Base: The base is the foundation of the table and provides support for the entire structure.

-

Tabletop: The tabletop is where the sand ball bearings are mounted. It is usually made of a non-magnetic material to prevent interference with the magnetic fields of the bearings.

-

Adjustment Mechanism: The adjustment mechanism allows for precise alignment and positioning of the sand ball bearings.

-

Supporting Structure: The supporting structure provides additional stability and support for the table.

Here is a table showcasing the dimensions of a typical sand ball bearing table:

| Component | Dimensions (mm) |

|---|---|

| Base | 1000 x 800 x 200 |

| Tabletop | 1000 x 800 x 50 |

| Adjustment Mechanism | 200 x 200 x 100 |

| Supporting Structure | 1200 x 1000 x 300 |

Applications of Sand Ball Bearing Tables

Sand ball bearing tables are used in a wide range of industries, including:

-

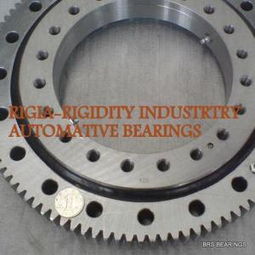

Automotive: Sand ball bearing tables are used for the assembly and maintenance of bearings in vehicles, such as cars, trucks, and motorcycles.

-

Manufacturing: They are used in the production of various machinery and equipment, such as conveyor belts, pumps, and compressors.

-

Energy: Sand ball bearing tables are used in power plants and renewable energy systems, such as wind turbines and solar panels.

-

Construction: They are used in the construction industry for the assembly and maintenance of heavy machinery and equipment.

Benefits of Sand Ball Bearing Tables

Investing in a sand ball bearing table offers several benefits:

-

Improved Efficiency: The precise alignment and positioning of sand ball bearings on the table ensure smooth and efficient operation of machinery.

-

Reduced Maintenance: The durable construction and high-quality materials of sand ball bearing tables contribute to longer service life and reduced maintenance costs.

-

Enhanced Safety: The stable and secure mounting of sand ball bearings on the table minimizes the risk of accidents and injuries.

-

Cost-Effective: Despite their initial cost, sand ball bearing tables offer long-term savings due to their durability and reduced maintenance requirements.

Conclusion

In conclusion, sand ball bearing tables are an essential tool for various industries, offering numerous benefits in terms of efficiency, safety, and cost-effectiveness. By understanding the construction, applications, and benefits of sand ball bearing tables, you can make an informed decision when selecting the right equipment for your needs. Whether you are in the automotive, manufacturing, energy, or construction industry, a sand ball bearing table can significantly enhance the performance and reliability of your machinery.