Sand Making Glass: A Comprehensive Guide

Have you ever wondered how glass is made? It’s a fascinating process that involves the transformation of raw materials, including sand. In this article, we will delve into the intricacies of sand making glass, exploring its history, the raw materials used, the manufacturing process, and the various types of glass that can be produced.

History of Glass Making

The art of glass making dates back thousands of years. The earliest known glass was made in ancient Egypt around 3500 BCE. Over time, the technique evolved, and by the Roman Empire, glass was being produced on a large scale. The use of sand as a primary ingredient in glass making became more prevalent during the medieval period.

Raw Materials

The primary raw material used in glass making is sand, which is a mixture of various minerals, including silicon dioxide (SiO2). Other materials, such as soda ash (sodium carbonate), limestone (calcium carbonate), and dolomite (magnesium carbonate), are also used to adjust the melting point and chemical composition of the glass.

| Raw Material | Chemical Formula | Function |

|---|---|---|

| Sand | SiO2 | Primary ingredient, provides the glass with its characteristic transparency |

| Soda Ash | Na2CO3 | Reduces the melting point of the glass mixture |

| Limestone | CaCO3 | Controls the melting temperature and chemical durability of the glass |

| Dolomite | MgCO3 | Improves the thermal stability of the glass |

Manufacturing Process

The process of making glass from sand involves several stages:

-

Melting: The raw materials are mixed and heated in a furnace to a temperature of around 1600掳C (2912掳F). This high temperature causes the materials to melt and form a liquid glass.

-

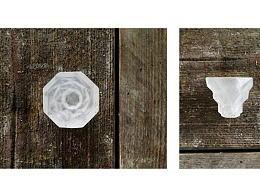

Forming: The molten glass is then poured into molds or blown into different shapes using a blowing pipe. Techniques such as casting, drawing, and pressing are used to create various glass products.

-

Finishing: Once the glass has cooled and hardened, it is polished, cut, and shaped to achieve the desired final product.

Types of Glass

There are numerous types of glass, each with its unique properties and applications. Some of the most common types include:

-

Flat Glass: Used in windows, doors, and mirrors, flat glass is produced by casting and rolling the molten glass into large sheets.

-

Bottles and Jars: These are made by blowing the molten glass into molds using a blowing pipe. Soda-lime glass is commonly used for this purpose.

-

Container Glass: Used for packaging food and beverages, container glass is made from a mixture of sand, soda ash, and limestone.

-

Specialty Glass: This category includes glass with specific properties, such as heat-resistant, bulletproof, and optically clear glass.

Environmental Impact

While glass making is a vital industry, it also has environmental implications. The high energy consumption and emissions from glass manufacturing processes are significant concerns. However, advancements in technology and recycling initiatives are helping to mitigate these issues. Recycling glass reduces energy consumption by up to 30% and raw material usage by 20%.

Conclusion

Sand making glass is a fascinating process that has been refined over centuries. From its humble beginnings in ancient Egypt to the sophisticated techniques used today, glass remains an essential material in our lives. Understanding the process and the various types of glass can help us appreciate its importance and the efforts being made to minimize its environmental impact.