Understanding Sanded MDF: A Comprehensive Guide

Sanded MDF, or Medium Density Fiberboard, is a versatile material that has gained popularity in various industries due to its durability, strength, and ease of use. If you’re considering using sanded MDF for your next project, this detailed guide will provide you with all the information you need to know about this remarkable material.

What is Sanded MDF?

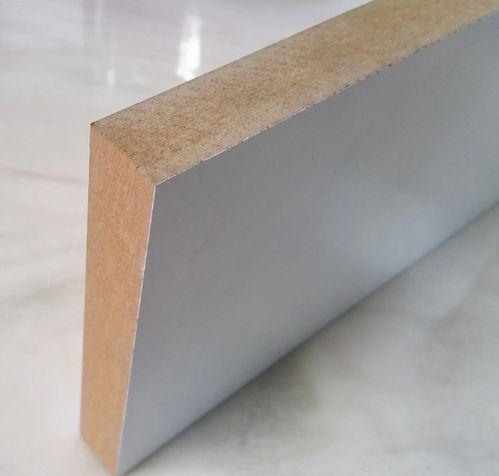

Sanded MDF is a type of engineered wood product made from wood fibers, resin, and wax. The wood fibers are obtained from the wood chips and sawdust of hardwood and softwood trees. These fibers are then mixed with resin and wax, and the mixture is compressed under high pressure and temperature to form a dense, uniform board.

Advantages of Sanded MDF

One of the main advantages of sanded MDF is its smooth surface, which makes it ideal for painting, staining, and gluing. Unlike solid wood, sanded MDF does not warp or expand, which ensures that your project will remain stable and durable over time. Here are some of the key benefits of using sanded MDF:

| Advantage | Description |

|---|---|

| Smooth Surface | Sanded MDF has a smooth, even surface that is ideal for painting, staining, and gluing. |

| Stable and Durable | Sanded MDF is less prone to warping and expansion, making it a stable and durable choice for your projects. |

| Easy to Work With | Sanded MDF can be easily cut, drilled, and shaped using standard woodworking tools. |

| Cost-Effective | Sanded MDF is a cost-effective alternative to solid wood, making it an ideal choice for large projects. |

Applications of Sanded MDF

Sanded MDF is used in a wide range of applications, from furniture making to construction. Here are some of the most common uses of sanded MDF:

- Furniture: Sanded MDF is commonly used in the production of cabinets, shelves, and other furniture pieces due to its smooth surface and stability.

- Building Materials: Sanded MDF is used in the construction industry for making interior doors, wall panels, and ceiling tiles.

- Home Decor: Sanded MDF is used in home decor projects, such as picture frames, mirrors, and decorative panels.

- Electronics: Sanded MDF is used in the electronics industry for making enclosures and other components.

Choosing the Right Sanded MDF

When selecting sanded MDF for your project, it’s important to consider the following factors:

- Grade: Sanded MDF is available in different grades, ranging from standard to premium. Higher-grade MDF has a smoother surface and is more suitable for projects that require a high-quality finish.

- Thickness: The thickness of the MDF board will depend on the size and weight of the project. Thicker boards are more durable and can support heavier loads.

- Finish: Sanded MDF is available in various finishes, including smooth, rough, and textured. Choose a finish that complements your project’s design and requirements.

Working with Sanded MDF

Sanded MDF is easy to work with, but there are a few tips to keep in mind to ensure the best results:

- Use sharp tools: Dull tools can cause splintering and damage to the MDF surface.

- Apply a sealant: To protect the MDF from moisture and other environmental factors, apply a sealant or varnish after painting or staining.

- Plan your cuts: Measure and mark your cuts carefully to ensure accuracy and avoid mistakes.

Conclusion

Sanded MDF is a versatile and durable material that is perfect for a wide range of projects. By understanding the benefits, applications, and proper techniques for working with sanded MDF, you can create high-quality, long-lasting projects that will stand the test of time.