Sand Drill Machine: A Comprehensive Guide

Are you looking to delve into the world of sand drilling machines? If so, you’ve come to the right place. In this article, we will explore the ins and outs of sand drill machines, providing you with a detailed and multi-dimensional introduction. Whether you are a seasoned professional or a beginner, this guide will equip you with the knowledge you need to make informed decisions.

Understanding the Basics

A sand drill machine, also known as a sand drilling rig, is a specialized piece of equipment used for drilling into sand or other loose materials. These machines are commonly used in construction, mining, and geotechnical engineering projects. The primary purpose of a sand drill machine is to create holes in the ground for various applications, such as installing foundations, extracting minerals, or conducting soil investigations.

There are several types of sand drill machines available, each with its unique features and capabilities. Some of the most common types include:

- Rotary Drill Machines: These machines use a rotating drill bit to bore into the ground. They are suitable for drilling through hard and soft materials, including sand.

- Impact Drill Machines: These machines use a hammering action to break up the material and create holes. They are ideal for drilling through dense and rocky formations.

- Air Drill Machines: These machines use compressed air to power the drill bit, making them suitable for drilling in areas with limited space or where electrical power is not available.

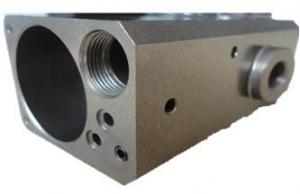

Key Components of a Sand Drill Machine

A sand drill machine consists of several key components that work together to ensure efficient and effective drilling. Here are some of the most important parts:

- Drill Bit: The drill bit is the cutting tool that actually makes contact with the ground. It comes in various shapes and sizes, depending on the type of material being drilled.

- Drill Pipe: The drill pipe is a long, hollow tube that connects the drill bit to the power source. It provides support and stability during the drilling process.

- Engine or Motor: The engine or motor provides the power needed to rotate the drill bit and drive the machine. It can be powered by electricity, diesel, or gasoline.

- Hydraulic System: Many sand drill machines are equipped with a hydraulic system that allows for greater control and flexibility during drilling operations.

- Control Panel: The control panel allows the operator to adjust various settings, such as drilling speed, pressure, and rotation direction.

Choosing the Right Sand Drill Machine

Selecting the right sand drill machine for your project is crucial for ensuring success. Here are some factors to consider when making your decision:

- Drilling Depth and Diameter: Determine the depth and diameter of the holes you need to drill, as this will help you choose a machine with the appropriate capacity.

- Material to Be Drilled: Consider the type of material you will be drilling through, as different machines are better suited for different materials.

- Power Source: Decide whether you need an electric, diesel, or gasoline-powered machine, based on your project’s requirements and available resources.

- Portability and Size: If you need to transport the machine to different locations, consider its portability and size.

- Budget: Set a budget and look for machines that offer the best value for your money.

Operating a Sand Drill Machine

Operating a sand drill machine requires proper training and knowledge of the equipment. Here are some tips for safely and effectively operating a sand drill machine:

- Read the Manual: Familiarize yourself with the machine’s operation by reading the manual thoroughly.

- Inspect the Machine: Before starting the machine, inspect it for any signs of damage or wear.

- Secure the Equipment: Make sure the machine is securely anchored to prevent it from moving during operation.

- Adjust the Settings: Set the drilling speed, pressure, and rotation direction according to the material being drilled.

- Monitor the Process: Keep an eye on the drilling process to ensure everything is running smoothly.