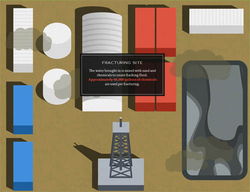

Fracking Sand: A Comprehensive Guide

Fracking sand, also known as proppant, plays a crucial role in the hydraulic fracturing process, commonly referred to as fracking. This article delves into the various aspects of fracking sand, including its composition, uses, production, and environmental impact.

Composition of Fracking Sand

Fracking sand is primarily composed of silicon dioxide (SiO2), which is commonly found in quartz. The sand particles are typically round and have a high strength-to-weight ratio. The size of the sand particles can vary, but they are usually between 0.425 and 0.210 millimeters in diameter.

Uses of Fracking Sand

Fracking sand is used to prop open the fractures created in the rock formations during the hydraulic fracturing process. This allows for the release of trapped oil and gas, making it an essential component in the extraction of unconventional resources such as shale gas and tight oil.

Fracking sand is also used in various other applications, including:

| Application | Description |

|---|---|

| Foundry Sand | Used in metal casting to create molds and cores. |

| Construction | Used as an aggregate in concrete and asphalt. |

| Water Filtration | Used in water purification systems to remove impurities. |

Production of Fracking Sand

Fracking sand is produced from natural deposits or through the processing of raw materials. The process involves several steps, including mining, washing, drying, and classifying the sand particles.

Mineral Extraction: The sand is extracted from quarries or mines, where it is mined using excavation equipment such as loaders and trucks.

Washing: The extracted sand is then washed to remove impurities, such as clay and silt, which can affect the performance of the sand in the hydraulic fracturing process.

Drying: The washed sand is dried to reduce its moisture content, which is crucial for maintaining the sand’s strength and size during the fracturing process.

Classifying: The dried sand is then classified into different sizes using screens or air classification systems to ensure that the sand meets the required specifications for use in hydraulic fracturing.

Environmental Impact of Fracking Sand

While fracking sand has numerous applications, its production and use have raised concerns regarding environmental impact. Some of the key environmental issues associated with fracking sand include:

Water Usage: The production of fracking sand requires significant amounts of water, which can be a concern in areas with limited water resources.

Water Pollution: The washing and processing of sand can lead to the release of pollutants into water bodies, potentially affecting aquatic life and human health.

Land Use: The mining of sand can result in habitat destruction and land degradation, particularly in areas where natural deposits are located.

Transportation: The transportation of large quantities of sand can lead to increased traffic and road wear, as well as potential accidents and spills.

However, advancements in technology and regulations have helped mitigate some of these environmental concerns. For example, the use of recycled sand and the development of more efficient water recycling systems have reduced the environmental impact of fracking sand production.

Conclusion

Fracking sand is a versatile material with a wide range of applications, particularly in the energy sector. While its production and use have raised environmental concerns, ongoing research and technological advancements are helping to address these issues. As the demand for unconventional energy resources continues to grow, the importance of responsibly managing the production and use of fracking sand will only increase.