Sand Battery Insulation: A Comprehensive Guide

When it comes to battery insulation, the choice of material is crucial. Sand battery insulation, also known as sand-filled battery insulation, has gained popularity due to its unique properties and benefits. In this article, we will delve into the details of sand battery insulation, exploring its composition, advantages, applications, and maintenance. Let’s embark on this journey to understand the ins and outs of sand battery insulation.

Composition of Sand Battery Insulation

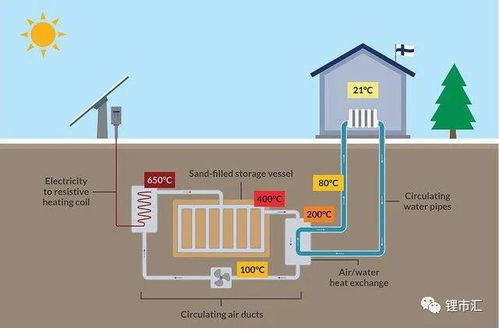

Sand battery insulation is primarily made up of sand, which serves as the main component. The sand used in this insulation is typically fine-grained and has a high thermal conductivity. Apart from sand, other materials such as resins, fibers, and fillers are added to enhance its properties. These materials work together to provide excellent thermal insulation and electrical resistance.

Advantages of Sand Battery Insulation

There are several advantages of using sand battery insulation:

-

High thermal conductivity: Sand battery insulation has excellent thermal conductivity, which helps in dissipating heat generated by the battery efficiently.

-

Electrical resistance: The insulation material provides high electrical resistance, ensuring that the battery remains safe from short circuits and electrical hazards.

-

Fire resistance: Sand battery insulation is highly fire-resistant, reducing the risk of fire outbreaks in battery-powered devices.

-

Environmental friendliness: The insulation material is made from natural sand, making it an environmentally friendly option.

-

Cost-effective: Sand battery insulation is relatively inexpensive compared to other insulation materials, making it an affordable choice for various applications.

Applications of Sand Battery Insulation

Sand battery insulation finds applications in various industries and devices. Some of the common uses include:

-

Automotive industry: Sand battery insulation is widely used in automotive batteries to provide thermal and electrical insulation.

-

Portable electronic devices: The insulation material is used in portable electronic devices such as smartphones, laptops, and power banks to ensure safe and efficient battery performance.

-

Industrial batteries: Sand battery insulation is used in industrial batteries to enhance their lifespan and performance.

-

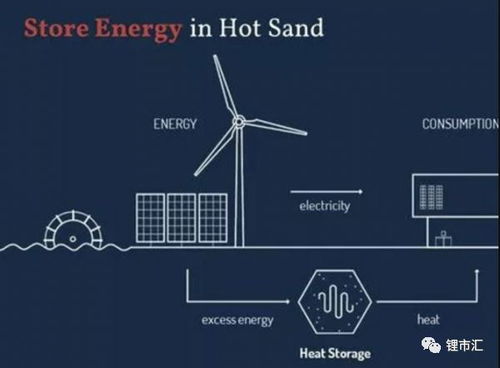

Renewable energy systems: The insulation material is used in renewable energy systems such as solar panels and wind turbines to protect the batteries from heat and electrical hazards.

Maintenance of Sand Battery Insulation

Proper maintenance of sand battery insulation is essential to ensure its longevity and performance. Here are some tips for maintaining sand battery insulation:

-

Regular inspection: Regularly inspect the insulation material for any signs of damage or wear. If any issues are found, replace the insulation promptly.

-

Keep the battery clean: Clean the battery and its surroundings regularly to prevent dust and debris from accumulating on the insulation material.

-

Avoid overloading: Overloading the battery can lead to excessive heat generation, which may damage the insulation material. Use the battery within its recommended limits.

-

Proper storage: Store the battery in a cool, dry place to prevent heat buildup and damage to the insulation material.

Comparison with Other Insulation Materials

When it comes to battery insulation, there are several materials available in the market. Let’s compare sand battery insulation with some of the other popular options:

| Insulation Material | Thermal Conductivity | Electrical Resistance | Fire Resistance | Environmental Friendliness | Cost |

|---|---|---|---|---|---|

| Sand Battery Insulation | High | High | High | High | Low |

| Glass Wool | Medium | Medium | Medium | Medium | Medium |

| Polystyrene |