Sand Grit Explained

Sand grit, a seemingly simple yet multifaceted material, plays a crucial role in various industries and everyday life. Whether it’s used for industrial purposes, as a cleaning agent, or even in the culinary world, understanding the properties and applications of sand grit is essential. In this detailed exploration, we will delve into the composition, uses, and benefits of sand grit, providing you with a comprehensive understanding of this versatile material.

Composition of Sand Grit

Sand grit is primarily composed of small, hard, and durable particles. These particles are usually derived from natural sources such as riverbeds, beaches, and quarries. The composition of sand grit can vary depending on its origin, but it typically consists of minerals like quartz, feldspar, and mica. These minerals contribute to the abrasive properties of sand grit, making it suitable for various applications.

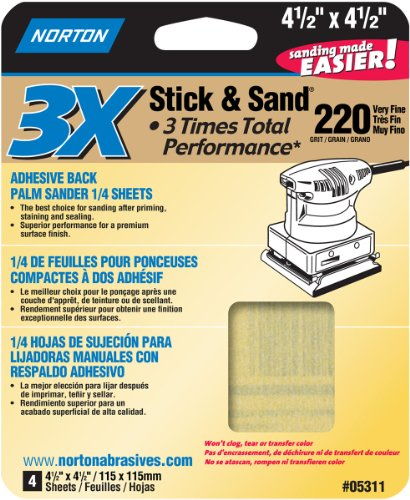

One of the key factors that determine the quality of sand grit is its particle size distribution. The particle size can range from fine sand to coarse gravel, and each size has its own unique properties and uses. For instance, finer sand grit is often used for polishing and cleaning, while coarser grit is more suitable for abrasive applications.

Industrial Applications of Sand Grit

In the industrial sector, sand grit finds extensive applications due to its abrasive and cleaning properties. Here are some of the common uses of sand grit in various industries:

| Industry | Application |

|---|---|

| Automotive | Used for sandblasting and surface preparation to remove rust, paint, and other contaminants from metal surfaces. |

| Construction | Used as an abrasive in concrete polishing, road construction, and as a component in asphalt mixtures. |

| Marine | Used for sandblasting ship hulls to remove barnacles and other marine growth, as well as for surface preparation. |

| Textile | Used in the textile industry for desizing, scouring, and bleaching processes. |

These are just a few examples of the many industrial applications of sand grit. Its versatility and effectiveness make it an indispensable material in various sectors.

Cleaning and Polishing Uses of Sand Grit

One of the most common uses of sand grit is in cleaning and polishing. The abrasive nature of sand grit allows it to effectively remove dirt, grime, and surface imperfections from various materials. Here are some of the applications of sand grit in cleaning and polishing:

-

Polishing metal surfaces: Sand grit is used to achieve a smooth and shiny finish on metal surfaces, such as car bodies, bikes, and machinery.

-

Cleaning glass and ceramics: Sand grit can be used to remove stains and scratches from glass and ceramic surfaces, restoring their original luster.

-

Removing rust and paint: Sand grit is an effective abrasive for removing rust and paint from metal surfaces, making it ideal for surface preparation.

Additionally, sand grit is often mixed with water to create a slurry, which can be used for cleaning large surfaces or for applying pressure to remove stubborn stains and contaminants.

Environmental and Health Considerations

While sand grit is a valuable material with numerous applications, it is important to consider its environmental and health impact. The mining and processing of sand grit can have negative effects on the environment, including habitat destruction and water pollution. Therefore, it is crucial to source sand grit from sustainable and environmentally friendly sources.

Moreover, sand grit can pose health risks if inhaled or ingested. It is essential to use appropriate safety equipment, such as masks and gloves, when handling sand grit to minimize exposure to potential hazards.

Conclusion

Sand grit is a versatile and valuable material with a wide range of applications. From industrial uses to cleaning and polishing, sand grit has proven to be an indispensable resource. By understanding its composition, uses, and environmental impact, we can make informed decisions about its use and ensure that it remains a sustainable and beneficial material for future generations.